- Preventive, predictive, and corrective maintenance services for critical equipment and machinery.

- Routine inspections, lubrication, and servicing of pumps, valves, compressors, and other essential assets.

- Expertise in offshore engineering for exploration structures, platforms, and offshore facilities.

- Design, analysis, and remodelling of exploration structures to enhance operational efficiency, safety, and structural integrity.

- Comprehensive planning and execution of maintenance activities during scheduled plant shutdowns and turnarounds.

- Coordination of manpower, equipment, and resources to ensure timely completion and adherence to project schedules.

- Proactive management of asset integrity to prevent safety incidents, environmental hazards, and regulatory non-compliance.

- Implementation of risk-based inspection programs and asset integrity management systems.

- We offer certified labor for various offshore oil and gas operations, including roles such as painters, welders, roughnecks, roustabouts, and more. These positions are crucial for ensuring the smooth operation of offshore rigs and platforms, as they involve tasks ranging from maintenance and construction to drilling support.

- Certified labor ensures that workers have received appropriate training and meet industry standards for safety and competence, which is essential given the challenging and often hazardous environment of offshore oil and gas operations.

- We offer the expert analysis you need to keep your assets running safely, efficiently, and productively.

- Working closely with our pipelines and process teams, our flow assurance team tackle dynamic and steady-state flow challenges, onshore or offshore. Whether it’s a start-up issue, dynamic slugging project, or analysis of wax or hydrate, or CO2 transportation challenge, the team has a wealth of experience in solving flow assurance challenges.

- Support many types of infrastructure across the energy landscape – onshore, offshore and subsea – from pipelines, structures and facilities to piping and vessels.

- We address design, integrity and operational challenges for onshore and offshore pipelines and subsea infrastructure conveying hydrocarbons, CO2 or hydrogen.

- The Non-Destructive Testing (NDT) methods that we offer are designed to comply with a wide variety of industry standards, Mining & Exploration contracts, and offshore & onshore specifications, as well as unique customer requirements.

ENGS provides inspection and testing services anywhere on earth while enhancing productivity, improving project quality, and Client Satisfaction.

ENGS provides world class rope access services, leveraging off our global experience and supported by our local resources. This capability provides the Oil & Gas, energy and mining sector with safe, reliable, proven rope access services that can be deployed fast and without ‘learning curve’ delays.

- As a one-stop procurement provider, we not only offer you the goods you need but a wide range of services too. ENGS is committed to embracing the latest technology, products, and services, and making them more widely available to our clients. We provide cutting edge alternatives to sources of supply.

Excelling in Front-End Engineering Design (FEED) and Precision Detailed Design

When we embark on a Front-End Engineering Design (FEED) process, our foremost commitment is to ensure unwavering quality, cost efficiency, and adherence to schedules, all while prioritizing safety and operational feasibility in our designs.

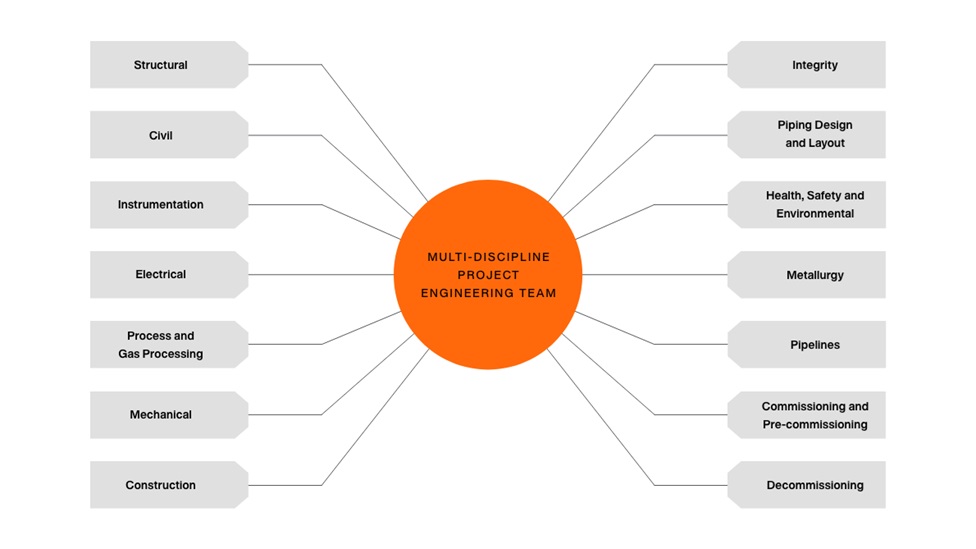

Leveraging the collective expertise of our global teams spanning Exploration & Production (E&P), Engineering, Procurement, Construction, and Maintenance (EPCm), as well as Operations, and Construction, we craft comprehensive front-end solutions aimed at minimizing both Capital Expenditure (CAPEX) and Operating Expenditure (OPEX) while concurrently enhancing safety measures and operational efficiency.

We meticulously apply the wealth of knowledge amassed through our extensive experience, ensuring its integration at the project’s inception stage to maximize its value and preemptively mitigate potential risks in later project phases.

Our proficiency in detailed design empowers us to accurately anticipate project requirements, thereby facilitating construction schedules through the timely provision of drawings, equipment, and materials, as well as the early procurement of critical long-lead items. This proactive approach enables us to support our clients in initiating construction activities sooner, thereby optimizing project timelines and outcomes.